Celebration day, yay! Today Carro & Rick finished sewing their kayaks. This marks the 21st day of building according to Carro.

It can be hard to remember all the details of a kayak build. Some stuff might be obvious for you but not for others. Many people like to experiment. When it comes to student builds, it is easy to lead someone down a slippery slope where things end up being harder than necessary. It has been known to happen…

However, more often than not the student builder comes up with a good idea and this was certainly not the first time during this build! Today we iterated on an idea and suddenly there is a new process going on, which might yield better results henceforth. Thanks Carro & Rickard for your positive going-forwards attitude!

So, what’s new?

- Our brand new cam straps which hold the coaming while sewing, might have a light silicone coating from the factory which can transfer to the kayak fabric and coaming. So we shield or tape where the straps are tight against the material. Oil and silicone are bad for Polyurethane stickyness.

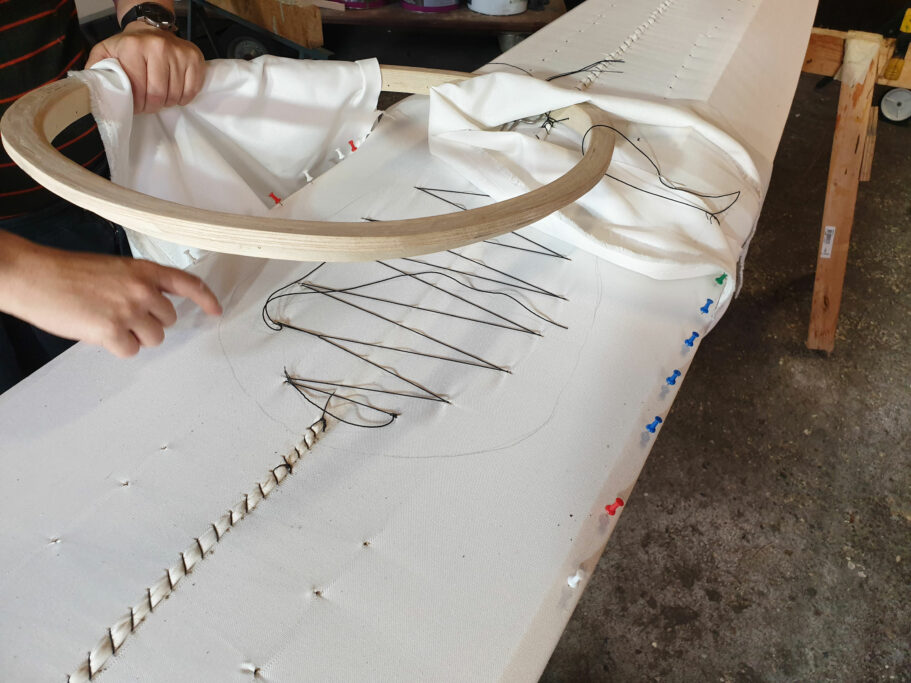

- We sew a couple of stitches at the front middle to keep the coaming dead center

- Once the extra zig-zag has tightened the cloth to the max, we secure the cloth with pins

- Now when sewing on the coaming back to front, the process is somewhat more forgiving and makes it easier to keep said coaming centered. The word “easier” being relative…