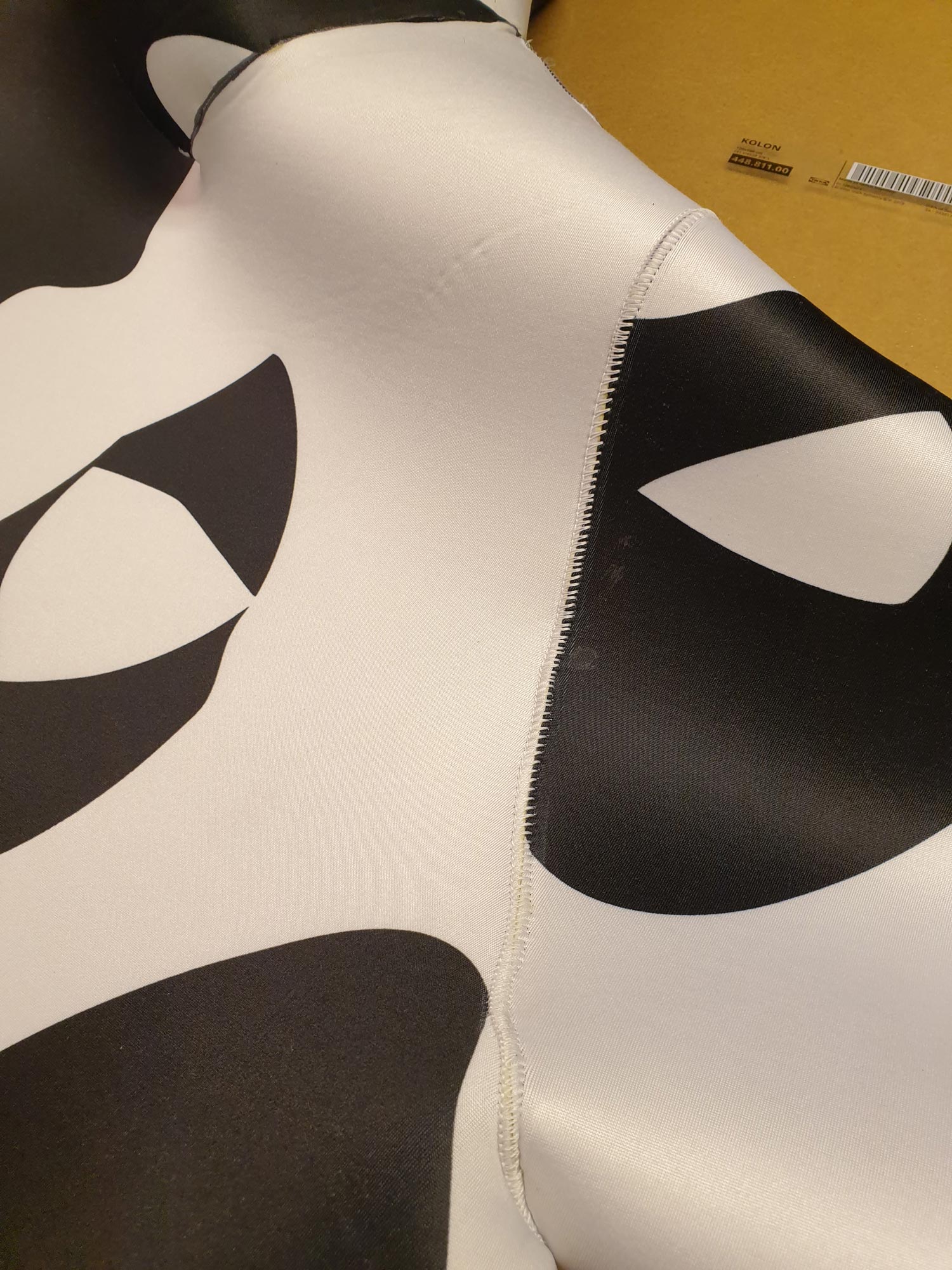

So it begins… after a few more tests it was time to finally start making my first neoprene Tuilik with my own neoprene graphics. For the qajaqally challenged: it’s a jacket with a hood and a spray skirt in one.

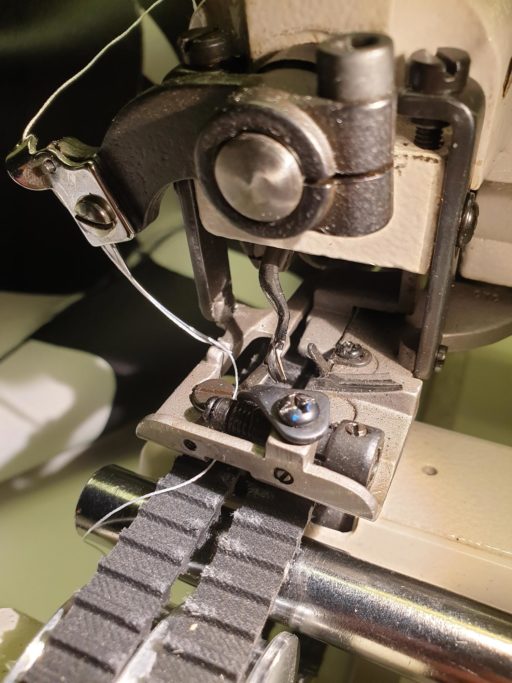

The plan was to glue the panels and then sew them, on at least one side, with my recently bought blind stitch machine. Maybe I should glue neoprene tape on the other side? Haven’t decided yet.

Using my other jackets and hoods as reference and inspiration was good for making patterns for a starting point. I have also tried software like VStitcher or Fusion360 but it seems the old fashioned hard paper and scissors work best for me at this stage. And the fact I don’t have a plotter to print the patterns for me at any convenient price or distance.

What seems to happen is that the patterns make for some kind of documentation for what I did last time, until the fit is right. I redo them all the time…

Being a noob with a blind stitch sewing machine and neoprene, I destroyed some glued “seams”. Also made a mess of the actual sewn seam with the presser foot in the original configuration. Well, I lightened the foot of a few parts and it got way better. This actually being a small jacket, I started out big so cutting away the destroyed seams is pretty straight forward.

There is a lot of tuning before you can actually do any work but none of this ripping happened to my small and flat test pieces I sewed a week before.

The motto is of course: learning by crashing! Those of you who knew me way back when might think some people never change, but I did! I have much shorter and grayer hair now… 🙂